large-scale complex programs with velocity & rigorous quality

The Talent, Capabilities and Expertise to Manage any Assembly Requirement

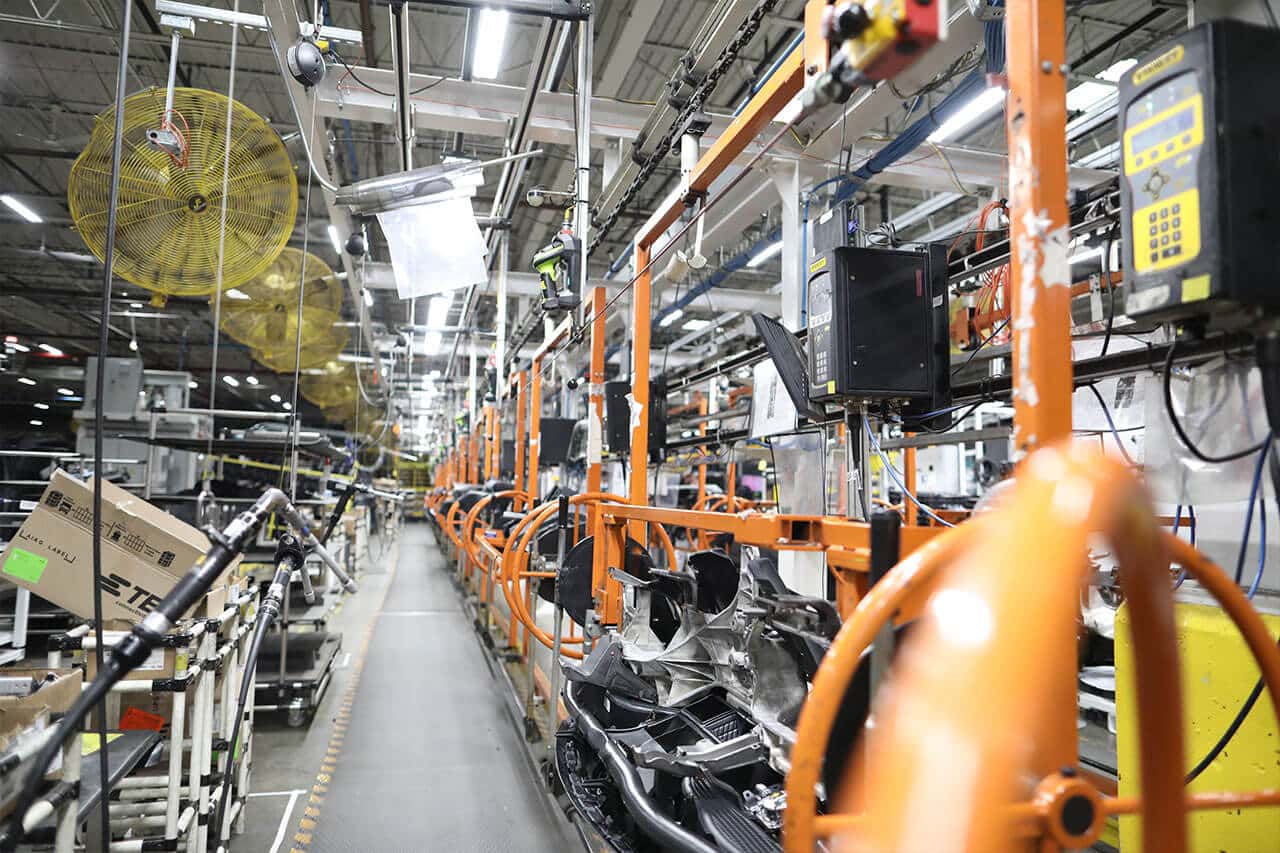

Detroit Manufacturing Systems is built for quality with the highest possible standards. Our clients entrust us in some of the most demanding manufacturing industries to deliver complex systems with consistency and velocity. We have created a culture of empowerment that allows our team and communities to rise to meet this challenge every day.

The Talent, Capabilities and Expertise to Manage any Assembly Requirement

Detroit Manufacturing Systems is has been built for quality at the highest possible standards. Our clients entrust us in some of the most demanding manufacturing industries to deliver complex systems with consistency and velocity. We have created a culture of empowerment that allows our team and communities to rise to meet this challenge every day.

Large Scale, Value-Add Contract Manufacturing

- Build to Print

- Full module assembly

- Sub-assembly of components (Robotic and Mechanical)

- Traceability

- Manufacturing system flexibility from batch build to “In-Line” custom sequencing to rigorous “Just-In-Time” delivery

- Create full assembly lines, sub-assembly stations, independent work cells

- Error proofing

- Launch, prototype, and pre-production parts

Manufacturing Systems

- Design and development of assembly and subassembly work cells

- Manual, semiautomated and fully automated solutions

- Injection molding

- 34 presses

- 180T – 2,500T

- Tool design and outsourcing

- Welding (ultrasonic, vibration, hot plate)

- Program and launch management

- Engineering: design for manufacturing (DFM), ECR support, continuous improvement

Supply Chain & Logistics

- High-velocity supply chain (inventory turns 24x+/yr)

- Global sourcing and supply chain

- Over 150+ active vendors

- Kitting, Vendor-Managed Inventory (VMI), Kanban

- Deliver to multiple customer locations

Inventory & Warehousing

- Over 450K sq. ft. of warehouse space

- IT and EDI integration

- Digital warehouse management (fall 2021)

- Multiple product variations seamlessly aligned to meet customer demand

- Thousands of part numbers across multiple product lines

Rigorous Quality

- IATF 16949 / ISO 14001 Certified

- PFEMAs

- Extensive error proofing / poka-yoke

- Full traceability, component serialization, and database

- In-process and end-of-line testing (includes e-test)

- In-process inspection and product release